4. dfSprayFoam

4.1. aachenBomb

Problem Description

This case simulates combustion inside a constant volume chamber based on an experimental setup at RWTH Aachen University. It can mimic, for example, the beginning of power stroke in a four-stroke diesel engine.

Chamber size (xyz) | 0.02×0.1×0.02m^3 |

Initial Gas Temperature | 800K |

Initial Gas Pressure | 5MPa |

Initial Gas Composition (mass fraction) | 23.4% O2, 76.6% N2 |

Fuel | n-heptane |

Fuel Temperature at the Nozzle | 320K |

Fuel Injection Duration | 1.25ms |

Total Injection Mass | 6mg |

Configurations Different from OpenFOAM Case

Cantera is used instead of the built-in modules of OpenFOAM to solve the chemical reactions. Therefore, a chemical mechanism file in YAML format is required in the case directory, and the full name of the mechanism file (“xxx. yaml”) should be the entry after the keyword CanteraMechanismFile in constant/CanteraTorchProperties. Non-reacting simulation can be conducted by switching the entry after the keyword chemistry from on to off in constant/CanteraTorchProperties.

Results

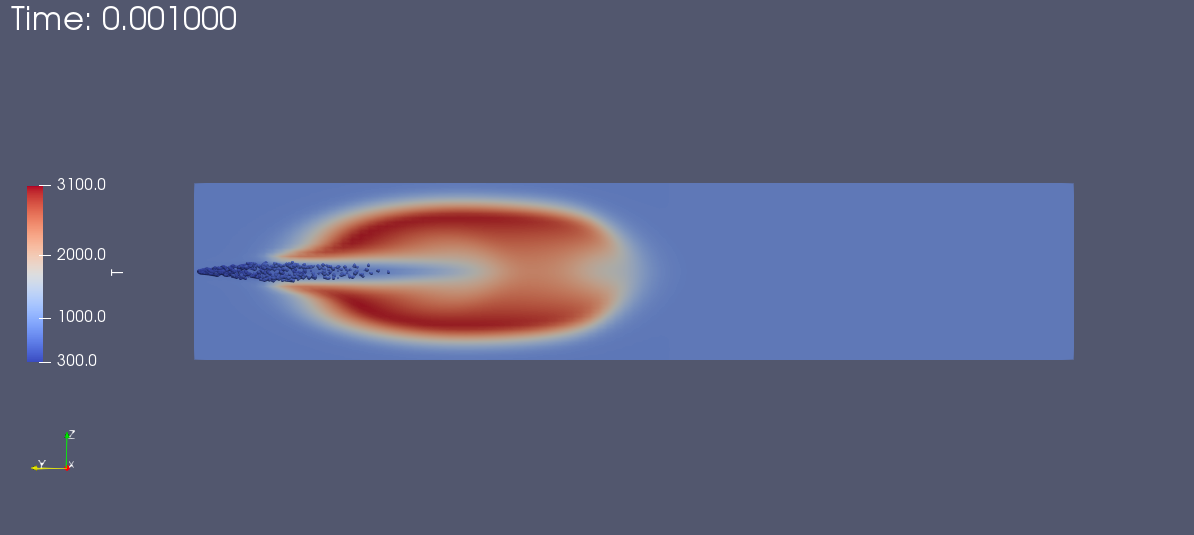

Visualization of temperature contours with large particle distribution

4.2. Sydney Spray Burner

Problem Description

A 2D-wedge case is used to simulate the dilute spray combustion processes inside a spray burner based on the experimental setup at Sydney University. It has been widely used for the study of droplet-chemistry-turbulence interaction.

Chamber size (wedge, 4 degree) | 0.104×0.500m^2 |

Initial Gas Temperature in Domain | 293K |

Initial Gas Temperature at Fuel Inlet | 267K |

Initial Gas Temperature at Pilot Inlet | 2493K |

Initial Gas Pressure | 1Bar |

Initial Gas Composition in Domain(mass fraction) | 23.4% O2, 76.6% N2 |

Fuel | C2H5OH |

Mass-flow Rate of Air Carrier | 150g/min |

Liquid Fuel Injection Rate | 23.4g/min |

Bulk Jet Velocity | 24m/s |

Bulk Burned Pilot Velocity | 11.6m/s |

Configurations Different from OpenFOAM Case

Cantera is used instead of the built-in modules of OpenFOAM to solve the chemical reactions. Therefore, a chemical mechanism file in YAML format is required in the case directory, and the full name of the mechanism file (“xxx. yaml”) should be the entry after the keyword CanteraMechanismFile in constant/CanteraTorchProperties. Non-reacting simulation can be conducted by switching the entry after the keyword chemistry from on to off in constant/CanteraTorchProperties.

Note

When running a wedge case with OpenFOAM, you may come across an error “Hitting a wedge patch should not be possible”. One solution is to comment out the lines with the “FatalErrorIn” call in src/lagrangian/basic/particle/particleTemplates.C. Details can be found in the thread [2].

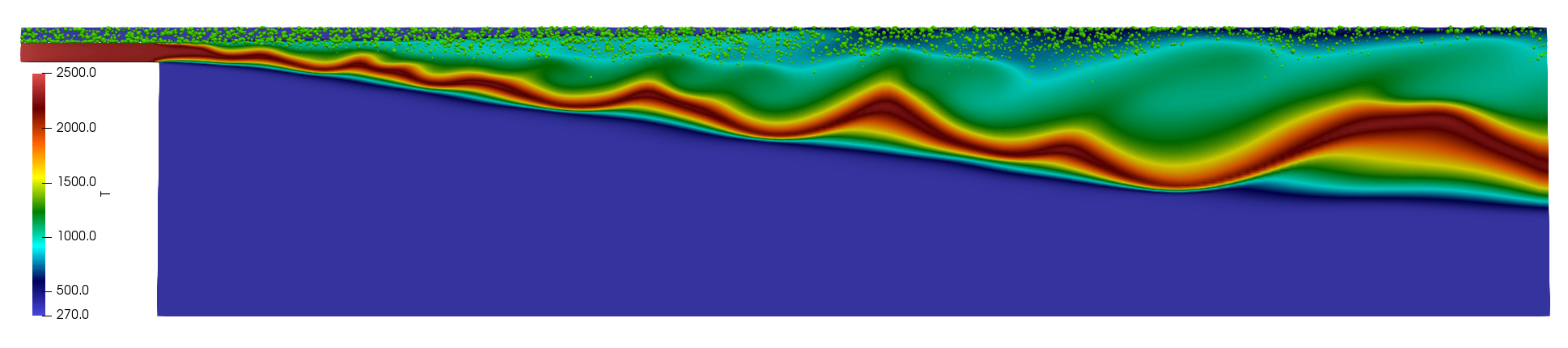

Results

Reference

[1] Gounder, James Dakshina, Agisilaos Kourmatzis, and Assaad Rachid Masri. “Turbulent piloted dilute spray flames: Flow fields and droplet dynamics.” Combustion and flame 159.11 (2012): 3372-3397.

[2]https://www.cfd-online.com/Forums/openfoam/89003-3d-spray-vs-axisymmetric-spray-dieselfoam.html